Maintaining your truck fleet in top condition isn't complicated. It all comes down to read more regular maintenance checks, spotting concerns before they escalate, tracking fleet condition, and adopting prevention-focused approaches. Scheduled inspections and repairs ensure optimal uptime, improved productivity, and security. Expert guidance from experienced technicians can help you master fleet maintenance through the smart implementation of digital tools, thorough documentation, and qualified team members. Start exploring this complete guide to fleet maintenance and unlock economical operations. There's so much to discover and uncover!

Core Concepts

Understanding the Critical Role of Routine Truck and Fleet Upkeep

Though it could feel overwhelming, understanding routine vehicle and fleet upkeep is essential for any successful business. You'll find the advantages of maintenance far outweigh the time and effort invested. Routine inspections and maintenance can greatly increase the lifespan of your vehicles, preventing expensive replacements. Moreover, there's a clear link between properly serviced vehicles and improved fuel efficiency. This results in decreased fuel spending, enhancing your bottom-line performance. Furthermore, regular upkeep can help identify minor concerns before they develop into major issues, saving you expensive repair costs down the line. Therefore, never discount the power of routine maintenance; it can be a real game-changer for your operation's success.

Identifying Essential Elements of a Effective Upkeep System

To ensure your fleet's longevity and efficiency, it's critical to recognize the vital elements of a well-designed maintenance program. You'll must comprehend the basic principles of maintenance, track the condition of your fleet regularly, and put in place preventive measures in advance. With these established, you're well on your way to decreasing downtime and optimizing productivity.

Core Program Maintenance Components

When it comes to enhance your fleet's efficiency and lifespan, implementing a comprehensive maintenance program is crucial. Critical elements of the program include scheduled inspections, routine servicing, and preventive repairs. Every component plays a crucial role in minimizing expensive failures and limiting downtime. While the rewards of a maintenance program are numerous, it's important to address the setup hurdles. These may include resource constraints and employee pushback. Yet, with proper planning, effective messaging, and focus on skill development, these barriers can be overcome. Remember that an well-designed maintenance program goes beyond fixing problems; it prevents them. It's an commitment in your fleet's longevity – and it's one that will yield significant returns.

Asset Performance Monitoring

As you explore the fundamentals of a well-designed maintenance program, understanding the critical role of fleet condition monitoring is essential. It extends beyond ensuring vehicle functionality, it focuses on optimizing fleet performance. Fleet monitoring systems provide a complete view of your fleet's status, allowing you to spot potential issues before they become serious.

Such tracking solutions track key metrics like fuel consumption, tire pressure, engine performance, and more. By utilizing this data, you're not just guaranteeing the lifespan of your fleet but also reducing unnecessary repair costs. Note that early detection is key in fleet management. Thus, implement reliable monitoring solutions and stay ahead of the curve. Don't merely address problems, forecast them. Monitor your fleet's status regularly and your business will run smoothly.

Implementing Preventive Measures

Although tracking your fleet's condition is crucial, putting preventive strategies in place is just as crucial to ensure a effective maintenance program. You need to spot potential issues before they transform into costly repairs or downtime. So, let's talk preventive measures.

An important strategy is creating a detailed maintenance checklist. This checklist should outline all necessary checks, tune-ups, and replacements. Routine engine monitoring, tire servicing, and oil changes are a given. However, remember to check smaller components like wipers, illumination, and filtration systems.

Your checklist should also include a schedule for all maintenance tasks. Following this plan ensures that your fleet maintains optimal performance. Don't forget, proactive maintenance saves time, money, and headaches in the long run.

Key Maintenance Tasks for Truck and Fleet Maintenance

To ensure your vehicles continue to be in optimal condition, you should focus on regular maintenance checks. These assessments cover scheduled maintenance inspections and essential system reviews. By adhering to these essential protocols, you'll extend your fleet's durability, optimize operational performance, and consequently, minimize expensive fixes.

Routine Equipment Inspections

Scheduled maintenance checks are your strongest line of defense against unexpected fleet and vehicle failures. These inspections offer you the ability to spot and address issues before they develop into serious accidents or expensive repairs. One of the primary benefits of routine maintenance is the reduction of operational delays, which can significantly affect your business's efficiency and profitability.

Vital Component Assessments

Expanding upon the significance of scheduled maintenance inspections, let's explore the key essential component checks that should be conducted regularly to ensure maximum truck and fleet performance. Begin by checking the brake system – ensure all components are functioning efficiently, from brake pads to fluid levels, as well as checking for leaks. Neglected, brakes may malfunction, leading to catastrophic incidents. Monitoring tire pressure is equally important. Insufficient pressure elevates fuel consumption and tire wear, while over-inflation risks a blowout. Purchase a reliable pressure gauge for precise readings. Note that tires should be cold during checks for best results. Regularly performing these critical checks can save you from costly repairs and potential accidents. Maintain safety on the road.

Fleet Efficiency: Preventative Maintenance Best Practices

When managing a fleet, it's essential that you focus on preventative maintenance to ensure peak efficiency. Implementing a comprehensive preventative scheduling system is crucial. This prevents unnecessary wear and tear, and lowers the chances of unscheduled downtime. You should schedule regular checks and servicing based on engine hours, mileage, time, or fuel usage. Remember each vehicle is unique and might need a personalized approach.

Maintenance education serves as an essential method to ensure peak efficiency. Equip your team with the essential skills to identify potential issues before they become serious problems. This reduces downtime but also lowers operational costs. The fusion of maintenance training and preventative scheduling will result in a more efficient and trustworthy fleet. Prevention is always better than cure.

Crucial Pointers for Transport Fleet Service and Rehabilitation

Even though fleet and truck maintenance and restoration might appear challenging, understanding the process can make it much simpler. Your initial step should be to learn about different maintenance methods. This expertise will allow you to spot concerns swiftly and accurately. Next, prioritize repair tasks based on the extent of repairs needed and the vehicle's role in your operation. Frequently check all units for developing concerns and tackle them quickly to avoid additional problems. Keep in mind, maintenance isn't only about repairs, it's about improving the vehicle's functionality and longevity. Lastly, make sure to select top-grade materials for restoration; they'll provide better durability and performance. Keep these tips in mind, and you'll handle vehicle fleet repairs and upkeep with ease.

Leveraging Technological Advances for Cutting-Edge Fleet Maintenance

To maintain a competitive edge in the trucking industry, it's vital to harness industry innovations for enhanced fleet maintenance. Technological advancements are revolutionizing the maintenance landscape. Make use of data analytics to track your fleet's efficiency and identify maintenance needs before they occur.

Modern tracking solutions effectively monitor engine health and efficiency, fuel consumption, and operator performance. Make use of these insights to plan proactive maintenance, decreasing expensive downtime.

Never ignore software updates. These improvements generally include critical modifications that improve your vehicles' reliability and protection. Remember maintaining your fleet involves more than basic repairs. You're managing in a technology-driven age, and following sector developments will help ensure your fleet's durability and success. By implementing the right processes, you can minimize costs and time, and enhance safety measures.

Common Questions

What Credentials Do You Need for a Qualified Fleet Service Technician?

You will require a proper certification, satisfying the standards of an established mechanic institution. Additionally, you'll need a proficient skill assessment, proving your knowledge in multiple facets of fleet repair and maintenance. Professional experience is also important!

How Often Should Fleet Vehicle Tires Be Replaced?

Just like the seasonal changes, it's important to inspect your fleet's tread depth regularly. However, it's generally recommended to swap out tires every 3 to 6 years, based on road conditions and usage patterns.

How Can You Identify Engine Issues in Trucks?

You can identify truck engine problems through signs such as abnormal engine noises and poor fuel performance. You may also notice excessive smoke, fluid leakage, or an illuminated check engine light that persists.

How Does Technology Impact Truck and Fleet Maintenance?

Technology is crucial in enhancing truck maintenance. Telemetry systems deliver real-time data, while analytical tools forecast issues before they happen. You'll experience less vehicle downtime, enhanced security and as a result, cost savings. It's a game-changer.

What Are the Specific Maintenance Requirements for Different Fleet Vehicles?

Various vehicles need unique maintenance schedules. One must account for the intended use, weight limits, and operating terrain, as these aspects substantially impact needed upkeep. Always adjust maintenance specific to the vehicle classification.

Conclusion

Ultimately, the key is ensuring your fleet operates efficiently, isn't it? Consistent upkeep isn't optional, it's absolutely necessary. By recognizing critical parts, performing regular inspections, using preventative strategies, and leveraging technological advances, you're going beyond simple upkeep, you're developing a high-performance fleet. And remember, fleet servicing isn't a problem, it's a pathway to enhancement. Stick with it, and you'll see your fleet's performance, dependability, and durability reach new heights.

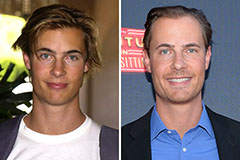

Erik von Detten Then & Now!

Erik von Detten Then & Now! Freddie Prinze Jr. Then & Now!

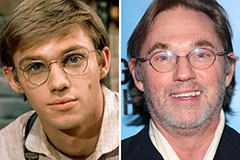

Freddie Prinze Jr. Then & Now! Robbie Rist Then & Now!

Robbie Rist Then & Now! Richard Thomas Then & Now!

Richard Thomas Then & Now! Kerri Strug Then & Now!

Kerri Strug Then & Now!